Welcome to the second part of my DIY Peugeot partner campervan conversion, basically in the first article I explained about putting the flooring in and the background of what i want to do with this car, you can see the video on YOUTUBE or see the article HERE.

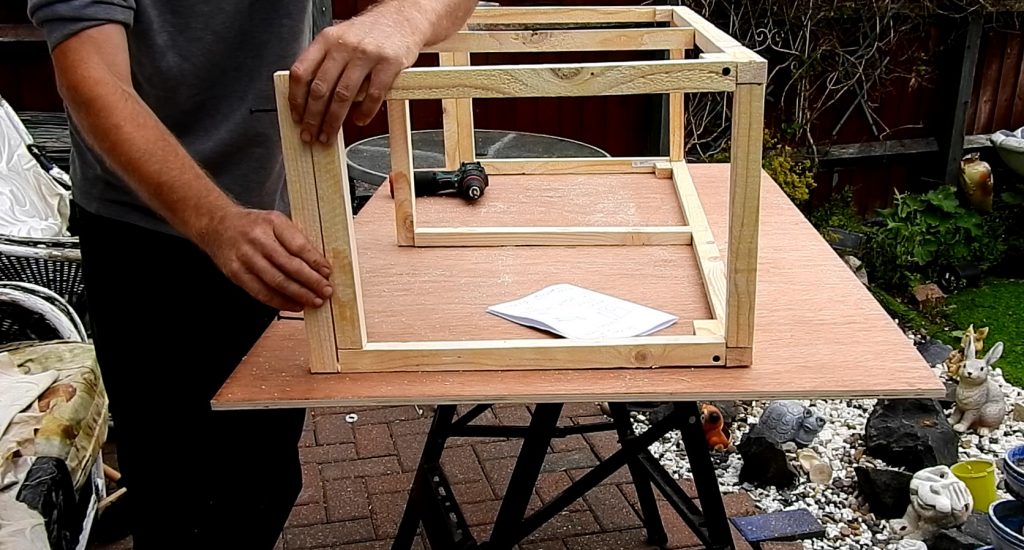

I first needed to find out if everything would fit so I measured & marked everything on the floor board to see which is the best way that I could get it, and the main thing is getting the toilet into the build as well. As have a flushable toilet that use for camping so the height of the boxes had to be high enough to fit that toilet in (as didn’t want to buy another one). So the way I first started was using some 25mm framework, chopping that down just using a chop saw two different measurements that actually worked out from the drawings that I used to get the measurements. The idea was to make a basically like a frame first and then extrude it out from the first time I did this, basically, I forgot to drill a little hole to put the screws in. So actually split the wood in the bottom corner there. So then what I did is then drilled little holes, my pilot holes for the screws to go in to make them framework.

Once that framework was made, then it was just a matter of screwing it all together to make the start of the frame. From there because the wood I had chosen wasn’t thick enough to be able to get two screws in and I’m not brilliant at doing corners in a three dimensional space I just used about two inch bits of offcuts of wood so they could screw in one way and then into the other. Once that was done, then I could extend it out, then I used extra bits on the front, to give that more support. The center is a bit wobbly but I’ve solved that further down the line by just put in some 45 degree angles to hold.

The first box I did was to house the toilet this will be a cupboard door that will open out. That will then support parts of the bed, as well as then the drawer unit that pulls out that gives the other support to the middle of the bed. I then tested the frame in the camper with putting the toilet in too see if it will work and the toilet will go far enough back. And it fitted perfectly. The next part was to do the end for the frame this was cut out using a circular saw from the plywood sheets I had brought, the one side was fine as just a rectangle, but the side that is at the back of the car, this is a shape the curves around the frame of the car, This was a bit more difficult to cut but eventually got the right shape.

Then it was on to making the next box frame, literally the same kind of principle, though I did put a bit more supports in and did the sides slightly different than the first box. The second box is going to be the one that goes behind the driver’s seat. Now, this one actually pulls out from the whole width of it to go towards the backseat so when you’re in a driving position the seats are pushed back. When you want to sleep, to just give that little bit of extra leg room which round about five or six inches maybe the drawer then extends out, then an extra cushion will actually go in there. So, the total length of the bed is just going to be just under six foot, which I’m 5ft 11 so should be enough length, because this originally was designed to sleep two, though upon doing this build now for one. So the width that I’m going for in total for the bed. It was working out to around about 109cm in the full width of the actual bed. Some of the other models that I’ve seen and everything else are about 80cm. but I wanted as much width as much as possible, just in case two can sleep and still be comfortable.

Though the width really was determined by a 2nd hand futon I had brought which the mattress with cover was just under 110cm, and the mattress of this futon was in two parts , so this made the framework for the seating area wider than again the other designs I had seen. But again, like any of these you make it to suit your needs. And this that’s why the frame for the kitchen unit is slightly slimmer on this design. Though the kitchen unit was design so that could fit one of the normal size single gas stoves in. The kitchen unit is being made in two parts, this is because I wanted the design , that if I wanted could still fit the single back seat in, so can have 3 people traveling, ie if went camping and had company, we could use the camper as well as the tent etc, though this may change in the future. And on the side of the body of the car just by the back door is the clip that the seat locks into so the main section could only go length ways upto this point. Then the other section can be bolted in and out if that seat was in.

After building the box units which really took me about a week and a bit, because I have a few medical problems, it means I can only do like a little bit as time have to start a little bit so I’d have to stop and so on. Now the next bit then was to actually get the carpet in I’d ordered two different types of carpet, both are proper camper carpet which is very thin and can stretch and mould it around any contours. I’ve gone for black that’s going to go on the floor and around the doors, wheel arches etc. But then on the actual boxes and everything else that’s going to be a light shade of blue.

Getting the carpet in on the floor, wasn’t too bad it was just literally just rolling it out, you just use spray adhesive, because I’d gone for two meters by three meters, so I just rolled it out, all the way out on the floor and going up the sides. I found doing it section by section was easy , spraying the floor and the underside of the carpet and just pushing it down. I found wearing disposable gloves which I use in my normal day job for cleaning out fish ponds to be easier so you don’t get friction burns on your hands. It was a bit awkward to get going but once you got the hang of it went down well.

Actually before putting the carpet in the one thing I realized is I hadn’t insulated around the wheel arches, so I just used the insulation that I’ve got that I used under the new floor board, first I cut it roughly to the shape, and then I just use spray adhesive around archway then stuck the insulation down, before fitting the carpet onto the new floor and I’d realized that there parts the board wasn’t wide enough to go the full width of the actual car more by the door, so needed some little cut outs of wood to slot in. Though because it was an unusual shape I just got some bits of a4 paper and kind of pushed it in and drew around it to make a rough template of the actual shape, then used that to trace on to the plywood to actually cut the shape out he other side was near enough the same, though, on the other side, because the boarding goes literally near enough all the way to the backseat. There’s a little bit of black trim this is slightly higher on one edge for the floor to sit flush down. I just had to chop away the top part using a jigsaw. So then the floor fits flush, and then the actual plastic could go back in to protect the wires by the back door.

Well as you can see so far it’s coming along pretty nice. Why not follow this journey of the conversion by subscribing to the youtube channel or even on facebook, twitter or instagram, see below